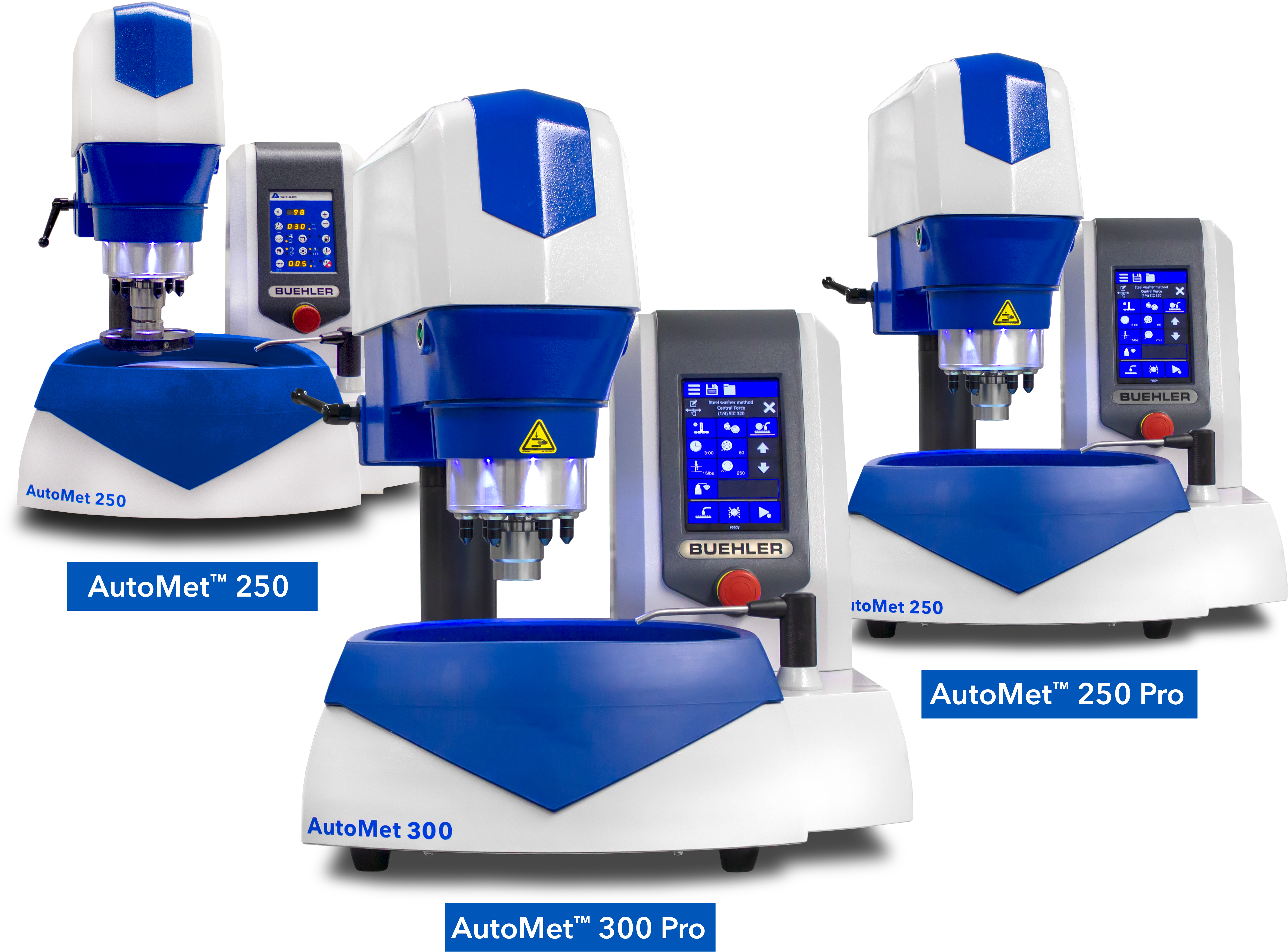

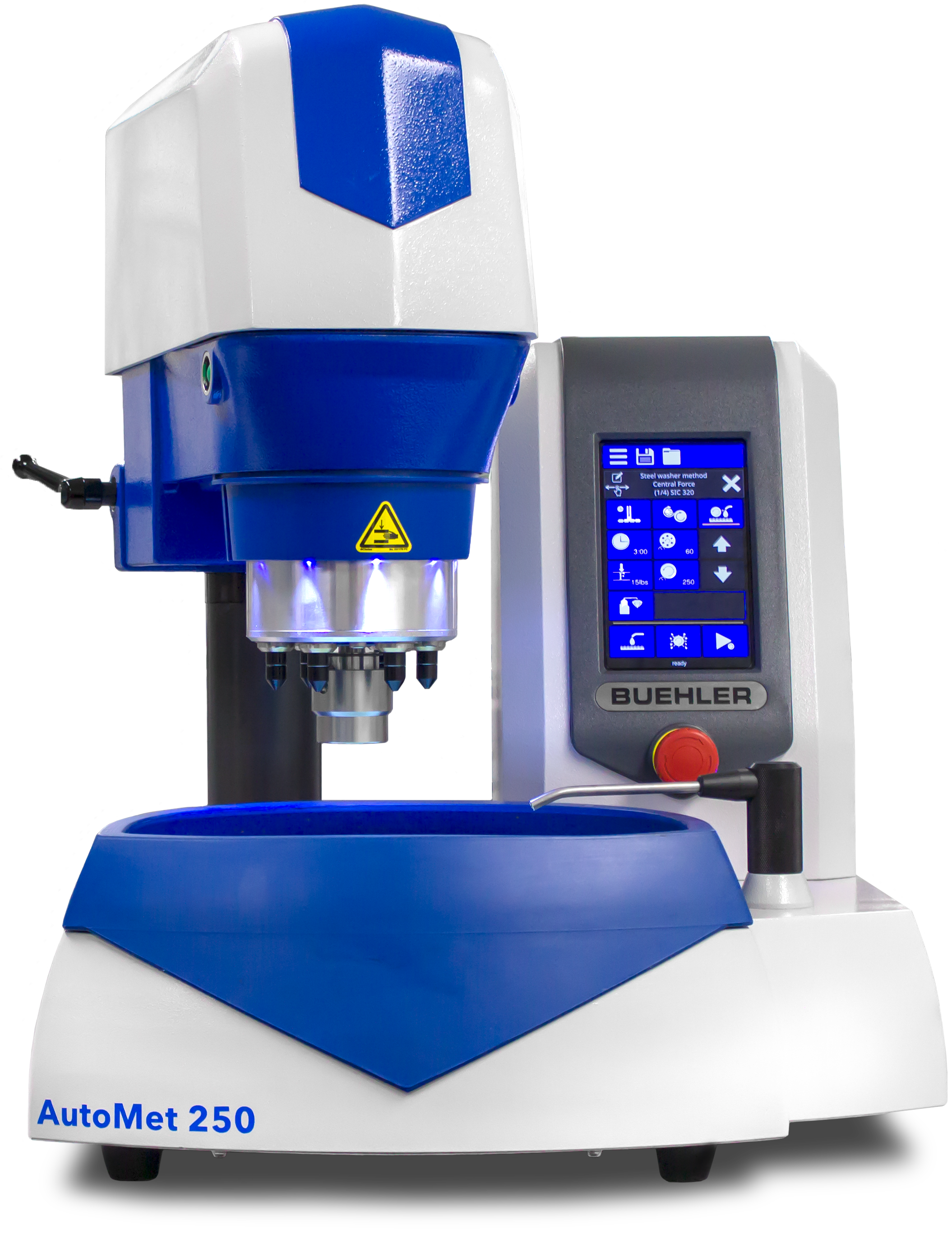

ITW company Buehler now offers AutoMet semi-automatic grinder-polishers. The AutoMet 250, AutoMet 250 Pro and AutoMet 300 Pro grinder-polishers are ideal for customers in material testing or demanding environments needing to process a high volume of samples. They feature a brand-new intuitive touch screen interface that is simple to learn and quick to operate. The AutoMet Pro models also include advanced programming features such as method storage and z-axis material removal to ensure consistent results regardless of operator.

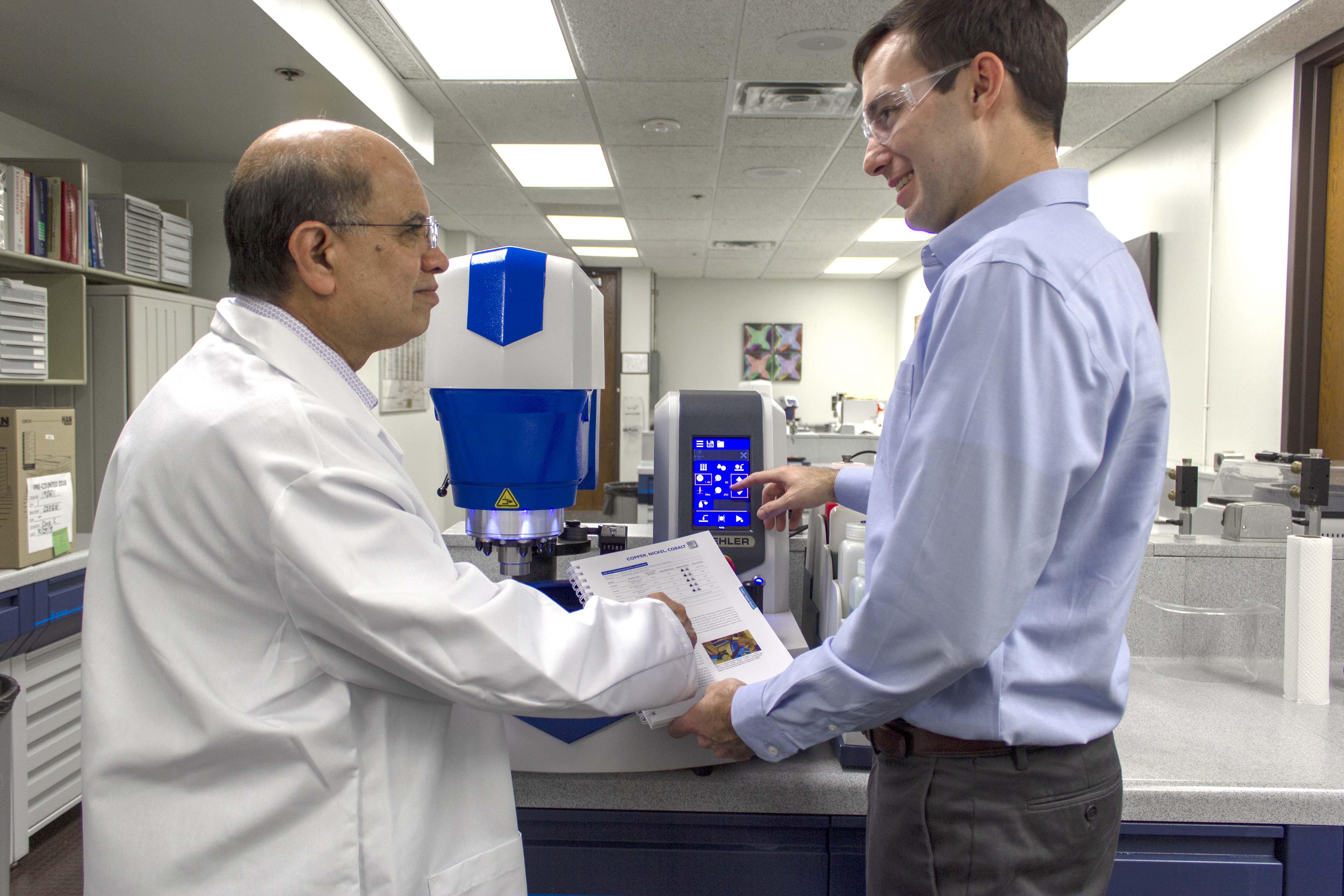

“From speaking to our customers, we knew that production labs need to move quickly, and they need a reliable grinder polisher that can be programmed no matter who is working the shift,” says Buehler global product manager Matthew Callahan. “So, the Buehler innovation team created the AutoMet Pro grinder polishers to expedite the sample preparation process and improve the quality of the samples while saving time and money in the training of laboratory technicians.”

“From speaking to our customers, we knew that production labs need to move quickly, and they need a reliable grinder polisher that can be programmed no matter who is working the shift,” says Buehler global product manager Matthew Callahan. “So, the Buehler innovation team created the AutoMet Pro grinder polishers to expedite the sample preparation process and improve the quality of the samples while saving time and money in the training of laboratory technicians.”

“The machine eliminates constantly setting the machine and the possibility of human error. It supports complex lab applications … so it also suitable for high-throughput labs — especially in the automobile, aerospace, medical device, electronics, heat treat, metals and other manufacturing industries.”

Buehler’s non-programmable AutoMet 250 Grinder-Polisher offers push-button controls and digital readouts. All AutoMet models have been redesigned for a new look and feel, while retaining the reliability that comes with the Buehler name. Quick cleaning features including an adjustable water spout, 360° bowl rinse, and bowl liners save time and effort during daily cleaning.

Reproducibility and automation can be further improved by integrating the Burst Dispensing System, which also optimizes abrasive usage to save on consumables spend. Another new highlight of the AutoMet grinder-polishers is Rinse and Spin … which cleans polishing surfaces and the platen at the press of a button. For more information, visit buehler.com.

Leave a Reply

You must be logged in to post a comment.