Many industrial applications require linear motion during their operating sequence. One of the simplest and most cost-effective ways to accomplish this is with a pneumatic actuator, often referred to as an air cylinder. Actuators are typically mechanical devices that take energy and convert it into some kind of motion. That motion can be in any […]

Actuators

Keeping the elements at bay

Keep these five key factors in mind when selecting mechanical components for harsh environments. Chad Carlberg Product Line Manager for Industrial Actuators Thomson Linear As electromechanical actuators and other mechanical motion components expand in capability for heavy duty applications, so does their capability to resist harsh conditions. Extreme temperatures, high particulate levels, chemical exposure, high-pressure […]

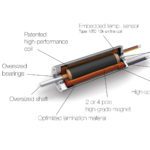

Direct-drive, high-resolution electric cylinders with integrated encoder

The SDLM-025-070-01-01 and SDLM-025-070-01-05 direct drive linear motors from Moticont, also known as electric cylinders, have built-in encoders, and feature high acceleration, high speed, high resolution, zero backlash, and zero cogging. These compact direct-drive linear motors with quiet linear plain bearings are just 1.00 in. (25.4 mm) in diameter and 2.75 in. (69.9 mm) long. […]

Finalists announced for Motion Control category of LEAP Awards – 2018

Finalists were announced on Friday, November 2nd for the inaugural LEAP Awards Motion Control Category. The competition was scored by a panel of independent engineering judges. The judges below were responsible for the Motion Control category. Dan Jones • President | Incremotion Associates Dan Jones started as a production worker at a motor company in the late […]

How to specify motion components for cleanroom environments: Part 2

In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we looked at how to reduce particle generation due to friction between moving components. In this second part, we’ll look at another source of contamination — outgassing — […]

How to specify motion components for cleanroom environments: Part 1

In this two-part article, we cover the products, materials, and features that designers and engineers should specify when choosing motion components for cleanroom environments. In part 1, we look at how to reduce particle generation due to friction between moving components. Designers of automation systems are tasked with many competing demands, such as balancing cost and performance, […]

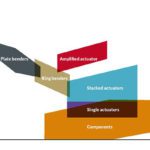

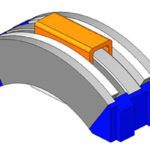

How does stiffness affect piezo output force and displacement?

Piezo actuators operate on the inverse piezoelectric effect: when voltage is applied, the actuator contracts or expands. But when the actuator is blocked from moving (by a load applied in the direction of travel), it generates a force. This relationship between displacement and force in piezo materials is an inverse relationship. In other words, the […]

How do rotary voice coil actuators work?

Most linear motion devices have a rotary equivalent, and voice coil actuators are no exception. While the versions depicted in most product images and videos are linear, rotary voice coil actuators fill a need for smooth, arc-shaped motion and torque production with fast response times. But unlike the design relationship between rotary and linear motors, […]

Electric motors: Trends in stepper, battery-powered, and integrated motion designs

Updated November 2019 ⚙️ From induction motors in electric vehicles to tiny coreless dc motors in drug-delivery equipment, electric motors continue to proliferate. Last year we saw consumer products, implantable medical devices, and automation of previously manual tasks spur the most innovation in motor design and use. This year those trends continue — and now […]

SERAPID supplies Meridian Lift for XXIII Olympic Winter games opening ceremony

The SERAPID solution has once again been chosen to provide dynamic stage action for the opening ceremony of the 2018 Olympic Winter Games in Pyeongchang, South Korea. SERAPID had previously provided an extensive stage lift system for the 2008 Summer Games in Beijing, China. The opening ceremony took place in the Pyeongchang Olympic main stadium, […]