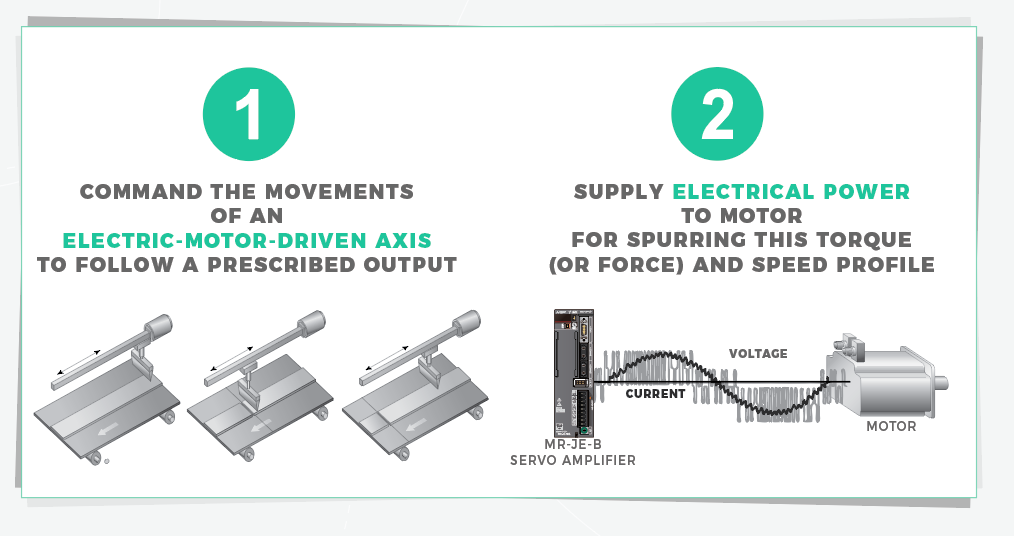

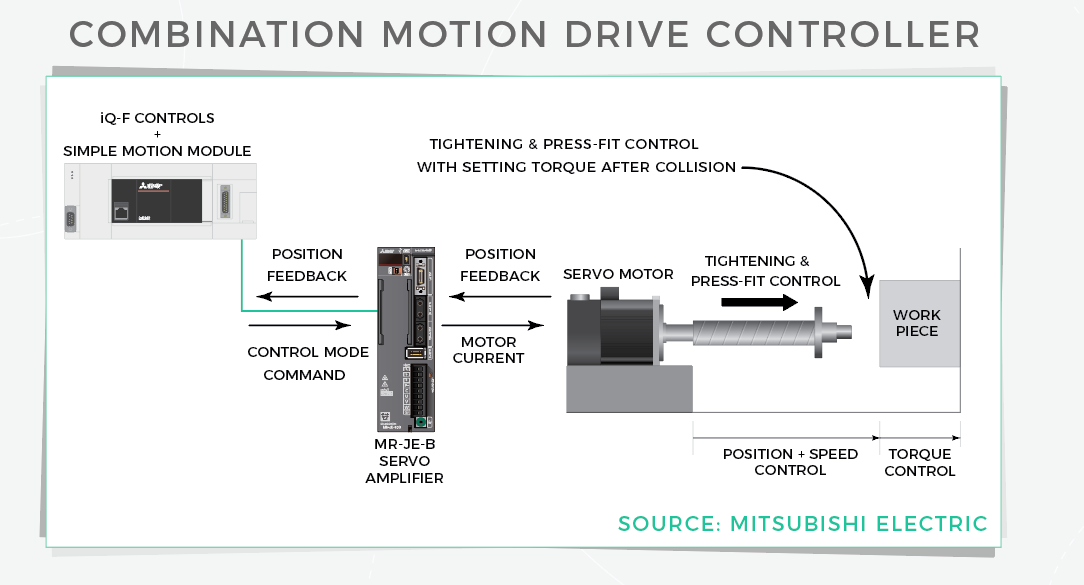

Combination motion drive controllers are components or subcomponent groupings that perform both electric and electronic functions in motion designs to command precision motion tasks from one or more motion axes. Combination motion-drive controllers first command the movements of an electric-motor axis (to follow a prescribed output) and second supply the electrical power to the electric motor for spurring this torque (or force) and speed profile. Sometimes called integrated drive controllers, these devices take various forms.

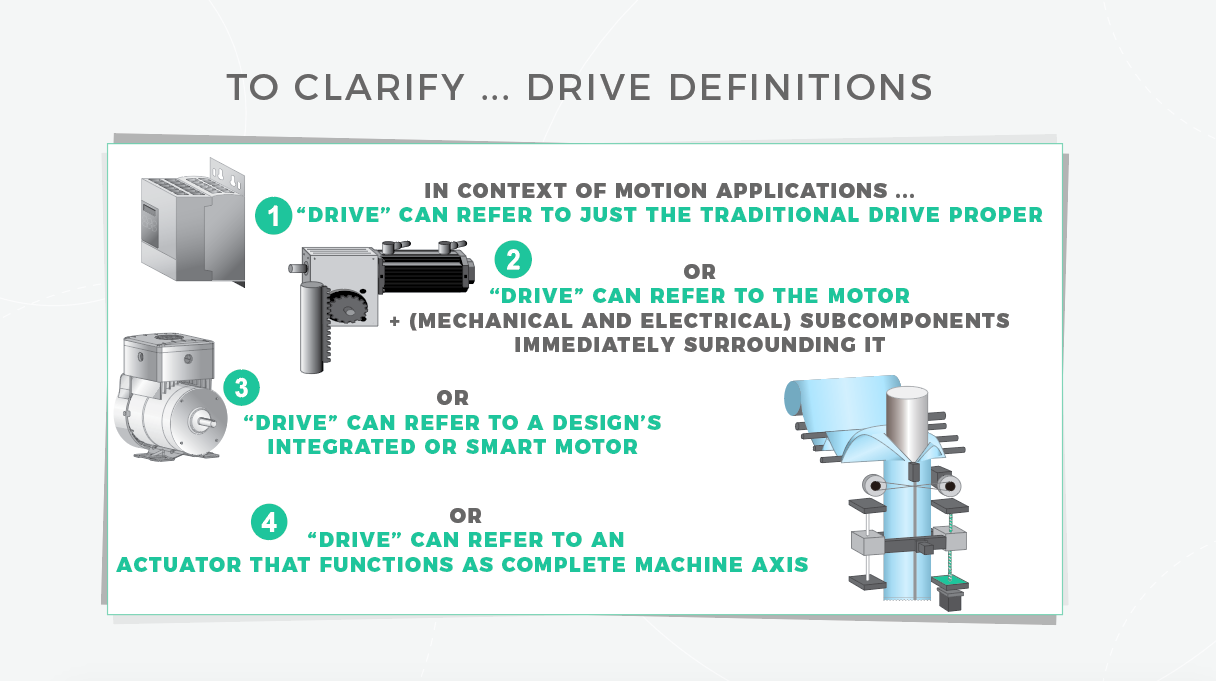

Note that especially with the blurring of lines between various motion-component functions, the word “drive” can mean different things.

Sometimes “drive” refers to just the traditional drive proper — the controlling power supply to the electric motor on an axis. Sometimes it refers to the motor and driving subcomponents immediately surrounding that motor. Elsewhere it refers to the integrated or smart motor in a motion design. Still elsewhere it refers actuators that function as complete machine axes networked to a larger system.

For our purposes here, we use the term combination motion drive controller to refer to setups that combine a proper amplifier in the form of a servo drive with controls. As machines and application objectives become increasingly complex, there’s increased demand for these types of integrated solutions both at the component and the machine level.

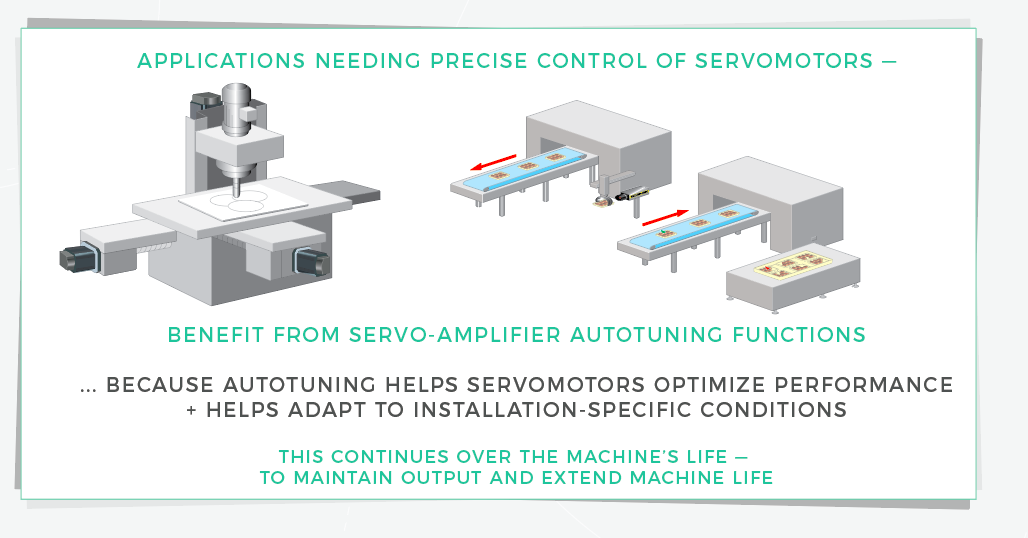

Applications needing precise control of servomotors — as in packaging equipment, pick-and-place installations, and machine tools — benefit from servo-amplifier autotuning functions. That’s because autotuning can help servomotors optimize performance and helps the axes’ motors adapt to installation-specific conditions. This continues over the machine’s life — continuously adjusting gains to minimize settling time and eliminate error … to maintain output and extend machine life.

Consider one combination motion-drive-controller setup: A micro PLC — which is basically a compact controller — fitted with an add-on module and connected to a servo amplifier. Here, a one-touch tuning function adjusts servo gains automatically — and automatic vibration suppression boosts servo performance.

End users and OEMs benefit from flexible motion designs — and this is a strength of combination drive controllers. Here, expandability and synchronization of many axes are common; depending on the exact permutation, these include gearing, camming, and registration. The latter is a high-speed discrete-motion task that adjusts for size and position variations of incoming product with mark detection … which ultimately maximizes finished product quality.

Of course, combination motion drive controllers require setup through some kind of programming environment. This most often takes the form of a graphical user interface or GUI software. Some offerings use strictly proprietary interfaces while others allow input in multiple programming languages — including those defined by IEC-61131, for example. Some such software supersedes additional software when it’s used in conjunction with hardware already loaded with firmware for specific motion tasks.

Lastly, combination motion drive controllers can simplify synchronization of axes. In some cases, this is through GUI software. Engineers configuring a machine can use the GUI to set synchronous-axis parameters. One iteration is that of applications using camming of some form or another. Here, control through software instead of mechanical linkages reduces maintenance and commissioning while boosting flexibility.

Leave a Reply

You must be logged in to post a comment.