Ben McGruder has been appointed Director of Customer Service and Inside Sales for Dorner Mfg. Corp. In his new position with Dorner, McGruder will lead Dorner’s Inside Sales team and oversee all aspects of the company’s customer service initiatives with customers and key accounts. McGruder brings more than 14 years of sales experience to Dorner. […]

Dorner

Dorner exhibits 3200 Series conveyor with ARB Technology and more at Automate 2017

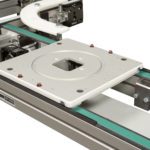

Dorner is exhibiting its new 3200 Series Conveyor with ARB™ Technology, along with its SmartFlex® and Precision Move platforms, in Booth No. 1059 at Automate 2017, April 3-6 in Chicago’s McCormick Place. Dorner manufactures packaged and custom conveyor solutions to meet the industrial, packaging and sanitary conveyor automation needs for a variety of industries. Dorner’s […]

Dorner launches latest 3200 series conveyor, highlights others at PackExpo

The newest product line from Dorner — the 3200 series conveyor with Intralox Activated Roller Belt (ARB) Technology — was on display at PackExpo earlier this month, along with several other key technologies from the conveyor manufacturer. The 3200 series is ideal for moving boxes and packages in applications that require merging, diverting and alignment. […]

Conveyor manufacturer Dorner appoints new territory manager for Georgia and Florida

Jon Schadeberg has been appointed a Territory Manager covering the states of Georgia and Florida for conveyor manufacturer Dorner Mfg. Corp. In this newly created sales position with Dorner, Schadeberg will be working with sales channel partners and key accounts to grow the company’s industrial and sanitary conveyor business. In June 2015, Schadeberg began his […]

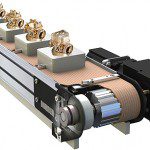

Motion systems application examples: Conveyors for many uses

Ranging from discrete product transport to bulk-material carriage, conveyor functions are as varied as the places in which they work. Engineers make conveyors meet specific applications by tailoring about a dozen conveyor design elements: belt or chain size, morphology and material; bases and support frames; controller, drive, and motor or motors; mode of belt or […]

Roller chain: Basics and sizing for power-transmission and conveying

Updated February 2018. || Engineers have used chains in motion systems for more than a century. They are versatile and reliable components to drive machinery and convey products. Now, advances in precision and technology let designers use chains in more applications than ever. Remote installations benefit from long-life chain that requires no lubrication, for example. […]

Advances in Timing Belts and Drives Ensure Conveyors Position Parts Precisely

In food and beverage lines, conveyors move parts into and out of machines, or they move parts through machines, act as a bridge between machines, or act as the main artery of a production line. An increasingly important capability of conveyor systems is to deliver more precise positioning. Positioning accuracy is influenced by friction, either […]

How to size and select belts and pulleys: An Engineer’s Guide

Updated May 2016 || Industrial belt drives consist of rubber belts that wrap around drive pulleys, in turn driven by electric motors. In a typical setup, the belt also wraps around one or more idler pulleys that keep the belt taut and on track. More after the jump. The main reasons that engineers pick drives […]