A traditional rotary encoder measures the position or speed of a rotating shaft, with mounting via a coupling or a hollow bore that allows the encoder to fit over the shaft. But not all rotating components have a shaft to which the encoder can mount. For example, direct-drive rotary motors — also known as torque motors, pancake motors, or Lorentz force motors, depending on their construction and operation — are designed without input or output shafts. Since traditional shaft encoders aren’t suitable, these applications typically use ring encoders — a type of rotary encoder characterized by a large hollow bore and a small axial height.

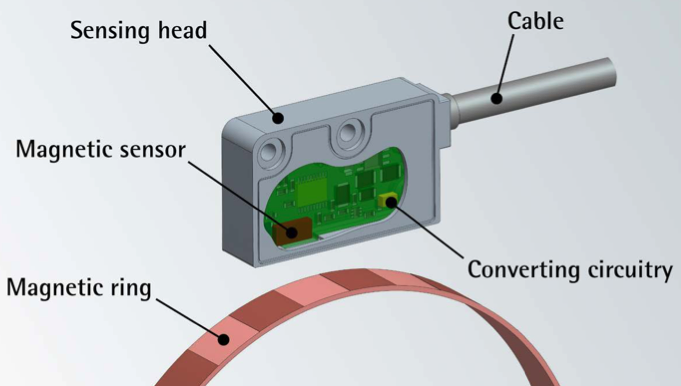

Ring encoders — also known as through-bore encoders or large bore hollow shaft encoders — consist of two components: a ring, which contains the measuring scale, and a scanning unit, which contains the sensing element and electronics. The encoder components are mounted separately and integrated directly into the application — for example, directly into a robot joint, or directly on the face of a NEMA C-Face motor. Unlike other rotary encoder designs, ring encoders don’t require support bearings, and they’re completely contact-free, so they can operate at higher rotational speeds and tolerate high shock and vibration loads.

Image credit: Lika Electronic

Depending on the required scanning head orientation, the encoder ring can be a radial or an axial type. Radial ring encoders have an encoder scale located on the outer “edge” of the ring, so that the scanning unit is located on the side of the ring and faces inward, radially toward the center of the ring’s bore. Alternatively, axial ring encoders have a scale located on the “face” of the ring, so that the scanning unit faces along the axis of the encoder.

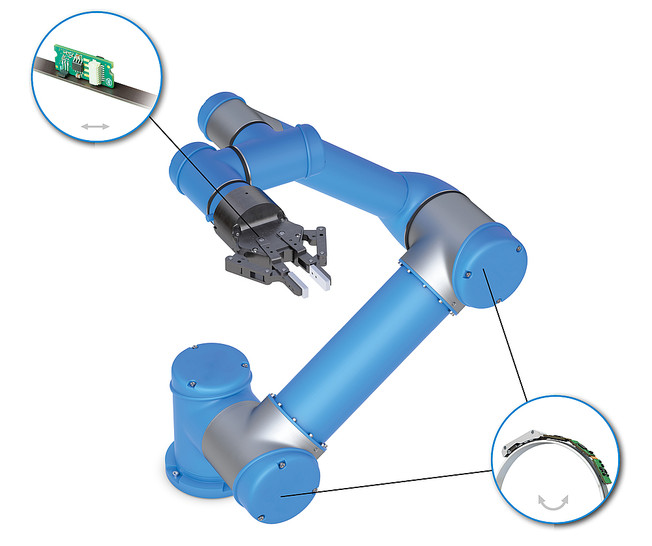

Image credit: RLS

Like other rotary encoders, both radial and axial ring encoders can be designed to provide incremental or absolute positioning information and are available with magnetic, optical, and even inductive scanning technologies to meet a wide range of accuracy and resolution requirements and withstand various environmental conditions. Although ring encoders that use magnetic or inductive scanning have relatively large mounting tolerances, optical ring encoders require more precise mounting and alignment.

Image credit: SIKO

Radial and axial ring encoders are often used in space-constrained applications — especially those that use rotary direct-drive motors — such as robot joints and rotary indexing tables and actuators. The ring encoder’s small axial height minimizes footprint, while the large bore provides a pathway for routing cables and pneumatic lines.

Leave a Reply

You must be logged in to post a comment.