QC Conveyors now serves more markets and applications with its new Flextrac Series modular plastic chain conveyors. Their space-saving modular design lets the conveyors handle the challenges of factory automation applications — whether fitting into new spaces or integrating existing machinery. Each Flextrac Series Conveyor consists of modular straight sections, horizontal curves, and vertical bends […]

Integrated Motion Systems

New matched motor-drive motion system from Kollmorgen

Kollmorgen’s new 2G Motion System is a servo solution based on the latest thinking about single-source, systems-based design. The 2G Motion System was designed specifically to harness the performance capabilities of Kollmorgen’s AKD2G servo drive and AKM2G servo motor. Motor and drive are precisely matched in every element (e.g. drive switching frequency, commutation algorithms, motor […]

Online tool from FAULHABER speeds drive system selection

The new Drive Selection Tool from FAULHABER lets users precisely determine the required drive system for their application quickly and easily. It’s especially useful for developers and application engineers who need to save time in the selection process. Only a little information, such as speed and torque, is sufficient in order to quickly determine the […]

Selecting miniature motors for surgical devices

By Keith Halbert, PhD • Portescap || Device makers and surgeons have for decades relied on sterilizable brushless direct current (BLDC) motors to meet the torque, speed, and reliability requirements of surgical handtools. Now surgical robotics are leveraging these same capabilities. Today’s surgical robotics and robotically-assisted surgical devices often require BLDC motors to meet demanding […]

New flat-top chain conveyor system from mk North America

Conveyor system designer and manufacturer mk North America, Inc. has added a new conveyor, VersaFlex, to its product line-up. The new flat-top chain conveyor system is intended to meet complex design needs and will replace the SBF-P 2254 conveyor line. Unveiled in Germany at Motek 2019, by Maschinenbau Kitz GmbH, the headquarters of mk Technology […]

Timing belt conveyors: benefits and uses

Industrial conveyors span a wide range of designs and configurations to suit specific purposes — from positioning delicate optical components for inspection to delivering automotive parts through an assembly line. When designing a conveyor, one of the first considerations is the conveying media to be used, which depends on the size, shape, and weight of the […]

Finalists announced for Motion Control category of LEAP Awards – 2019

Finalists were announced on November 5th for the second annual LEAP Awards Motion Control Category. The competition was scored by a panel of independent engineering judges. Below are descriptions of these worthy Motion Control finalists. The overall winner will be recognized at a ceremony in Santa Clara, Calif. in conjunction with the Healthcare Robotics Engineering […]

Efficient integrated gearmotors power intralogistics application

The intralogistics industry is a fastest-growing market — and one motion-component supplier aims to address the industry’s unique needs. “Three of the world’s top five material-handling suppliers use NORD drive technology, and we have long-term supply agreements with two of the suppliers,” says NORD Gear Corp. president and CEO Torsten Schultz One solution for intralogistics […]

White vinegar lines employ dry-lubrication and other conveyors

Rising demand for white vinegar recently prompted French condiment and seasoning company Charbonneaux-Brabant to install a Sidel PET line in their new Vauvert production plant. There the company bottles white vinegar in 1 and 1.5-l formats in a flexible operation that continuously changes to satisfy supply chain and distribution demands. In fact, growing use of […]

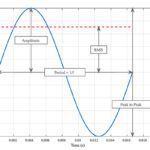

How is machine vibration defined?

Machine vibration is a normal, and typically unavoidable, result of moving and rotating parts, often caused by standard manufacturing and assembly tolerances that lead to clearances between mating parts or imbalances in rotating parts. And while routine machine wear can cause vibration to increase over time, when a machine experiences a significant or sudden increase or […]