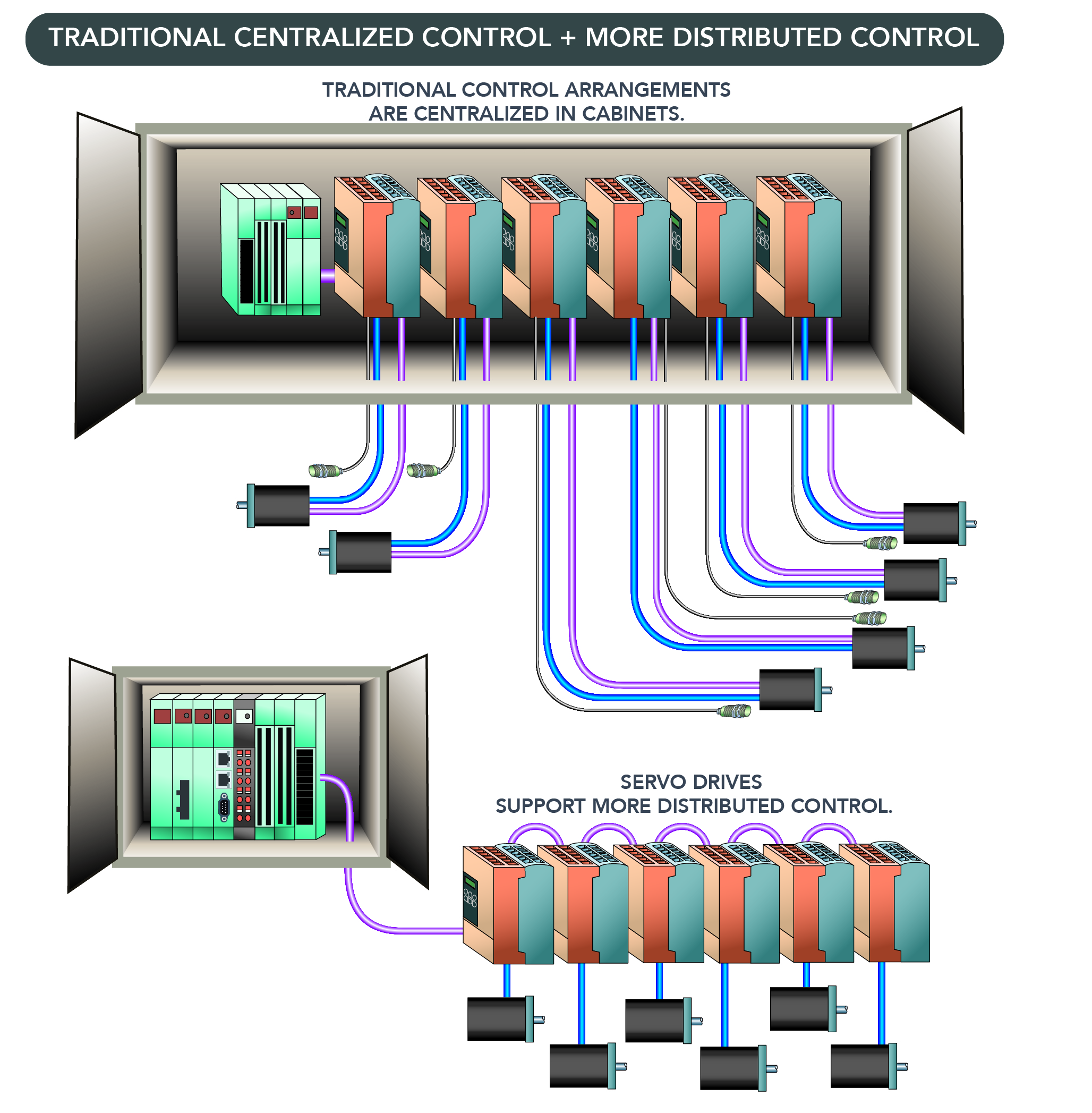

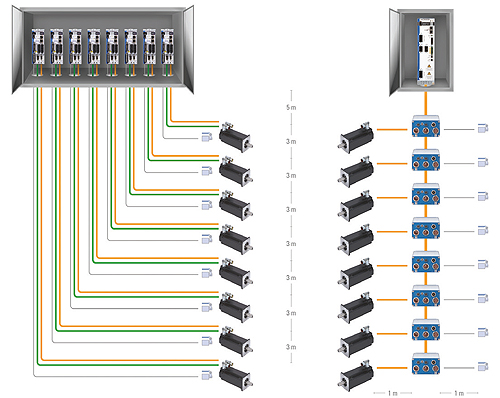

Article updated August 2019 || Traditional servo-system architecture consists of a power supply, a motion controller, and servo drives all housed in one location that is typically a control cabinet located away from the machine. Then each motor connects to the control cabinet by two cables … one for power and one for feedback. This centralized architecture results in significant time and cost for routing, managing and connecting all of the cables. It also requires a larger control cabinet to house the multiple components, and dictates the need for forced cooling (air conditioning) in the cabinet due to the heat generated by the numerous electronic devices inside.

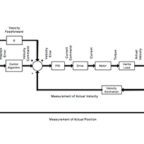

With intelligent servo drives, however, it’s possible to move the drives out of the control cabinet and closer to their motors. This is called a distributed architecture — sometimes also called a distributed control system or DCS. Typically in a distributed architecture, more intelligence resides in the servo drive — up to and in some cases including the motion-trajectory calculations.

If the axes must be tightly coordinated, as is the case with interpolated motion, the motion trajectory is calculated by the controller. If the motions of the axes are independent, the trajectory calculations can be carried out within each individual drive.

Communication between the drive and the control is facilitated by a network bus such as DeviceNet, some form of Ethernet, or SERCOS.

The three primary drawbacks of centralized architecture mentioned above — extensive cable management, cabinet size, and cooling requirements — are mitigated with distributed architecture. With the drives located close to the motors and a central power module supplying all components, the amount of cabling required is significantly reduced.

Moving the drives out of the control cabinet also trims the necessary cabinet size and at the same time, lessens the need for cooling.

Another benefit of the distributed architecture is higher reliability because fewer cables means fewer connection points … and shorter cables reduce the opportunity for electrical interference or noise.

While less cabling and the resulting cost and reliability improvements are attractive reasons to use distributed architecture, it’s not always feasible to locate the drives near the motors. This could be due to environmental reasons, such as excessive heat near the machine or process, or because of physical space restrictions in the machine design.

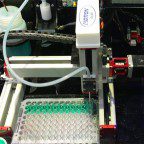

Distributed control system (DCS) with the use of integrated motors

Distributed control is also achieved by using integrated motor-drive systems, which further reduce wiring by doing away with the need for motor-drive cables.

Integrated motor-drives are the next step in component integration, but may offer fewer options (for feedback or I/O, for example) than traditional systems. Integrated motor-drives are also sometimes limited in their power output due to the heat dissipation required to protect the drive.

Even so, for designers and machine builders looking to simplify machine layout, integrated motor-drive systems offer a compact modular solution for DCS arrangements.

Leave a Reply

You must be logged in to post a comment.