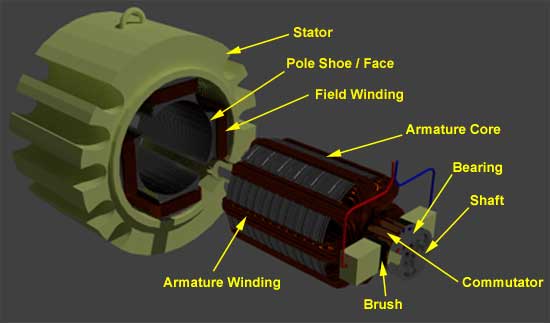

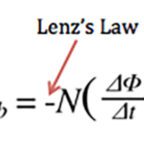

DC motors are constructed with two major parts: the rotor and the stator. The rotor has a ring-shaped iron core with slots that hold coils, or windings. Following Farady’s law, when the core is rotated in a magnetic field, a voltage, or EMF, is induced in the coils. This induced EMF causes current to flow, known as eddy current.

Image credit: electrical4u.com

Eddy currents are a form of magnetic loss, and the power loss due to the flow of eddy currents is referred to as eddy current loss. (Hysteresis loss is another component of magnetic loss.) These losses produce heat and reduce motor efficiency.

The amount of eddy current loss depends on several factors, including:

- the magnetic flux density

- the frequency of the induced EMF (the frequency at which the polarity of flux changes)

- the thickness of the magnetic material

Pe = Ke * B2 * f2 * t2

Where:

Pe = eddy current loss

Ke = eddy current constant

B = flux density

f = frequency of magnetic reversals

t = material thickness

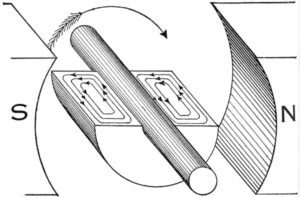

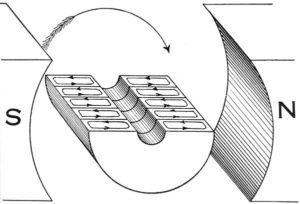

The development of eddy currents is influenced by the resistance of the material in which they flow. For any magnetic material, there is an inverse relationship between the material’s cross-sectional area and its resistance, meaning that a reduction in area causes an increase in resistance, and in turn, a decrease in eddy currents. One way to achieve a reduction in cross-sectional area is to make the material thinner.

This is why armature cores are made up of many thin pieces of iron, rather than a large, solid piece. These individual, thin pieces have a higher resistance than one solid piece, and therefore, produce less eddy currents and experience lower eddy current loss.

This is why armature cores are made up of many thin pieces of iron, rather than a large, solid piece. These individual, thin pieces have a higher resistance than one solid piece, and therefore, produce less eddy currents and experience lower eddy current loss.

The individual iron pieces that make up the armature are referred to as laminations.

Image credit: wikipedia.org

These laminations are insulated from each other, typically by a lacquer coating, to prevent the eddy currents from “jumping” from lamination to lamination. The inverse-square relationship between material thickness and eddy current loss means that any reduction in thickness will have a significant effect on the amount of loss. Because of this, manufacturers strive to make armature core laminations as thin as practical from a manufacturing and cost standpoint, with modern DC motors typically using laminations that are 0.1 to 0.5 mm thick.

Feature image credit: brighthubengineering.com

Leave a Reply

You must be logged in to post a comment.