Despite the benefits of using medium voltage AC drives for high horsepower motors, low voltage technology holds a dominant place in the AC drive market, for both low- and high-power applications. There are multiple reasons for this, not the least of which are cost and availability. Medium voltage drives have historically been custom-engineered solutions, with low-volume production, higher cost, and relatively long lead times.

Even though manufacturers are now offering more standard medium voltage (MV) drive options, and advances in high-voltage semiconductor technology have lowered the cost of electronics, they remain significantly more expensive (at least in terms of initial purchase price) and less readily available than low voltage drives.

Medium voltage drives draw less current than low voltage drives for the same power output. The lower current draw not only saves energy, it also allows the use of smaller, lower-cost cables. But low voltage drives are offered as standard products by a wide range of manufacturers, whereas medium voltage drives are still mostly custom-engineered products.

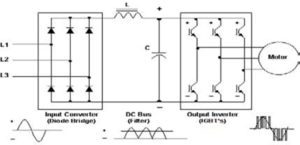

Low voltage (LV) drives can be either voltage source inverter (VSI) or current source inverter (CSI) types, but VSI types with pulse-width-modulation are the most common. Voltage source inverter, pulse-width modulation (VSI-PWM) drives typically use insulated-gate bipolar transistor (IGBT) switching devices in the inverter section. IGBTs have a high switching frequency, which minimizes harmonics and reduces motor heating. But the drawback of this higher switching frequency is that it results in a higher rate of voltage rise (dV/dt), which can cause reflected waves that damage the motor insulation and cables. Output reactors or filters can reduce the reflected waves, but they add cost to the drive system.

Although they operate at a lower voltage, LV drives are often used with medium voltage motors—especially motors rated at 2300 or 4160 V. In order to use an LV drive with a medium voltage motor, a step-up transformer is added to the drive. The transformer increases the inverter output voltage to match the motor voltage. For applications with only single-phase supply, LV drives are also capable of operating on single-phase voltage input and supplying three-phase voltage output to the motor.

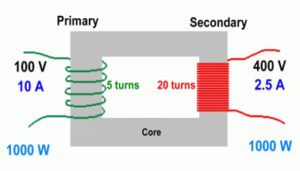

The ratio of voltages is directly proportional to the ratio of turns, while the current ratio is indirectly proportional to the turns ratio.

Image credit: Trishul Windings Ltd.

In cases where high starting torque (typically above 150 percent) is required, the low voltage PWM drive can be modified to use flux vector control. Also referred to as field oriented control (FOC), this method provides independent control of the magnetizing and torque-producing components of the stator current, resulting in more consistent torque output.

Low voltage drives offer a solution for both low- and high-power applications. And while medium voltage drives have the benefit of less current draw and lower energy usage, low voltage drives are often chosen for their relatively lower cost, smaller size, and better availability.

Leave a Reply

You must be logged in to post a comment.