Kollmorgen’s new EKM series of enhanced, high-performance, brushless ac servo motors are Mil-Spec 810E rated and IP67 sealed for duty in harsh environmental conditions. They are supplied standard with a stainless-steel shaft and chemical agent-resistant paint for reliable duty in harsh environmental conditions. The EKM brushless servo motors feature high power and torque density and […]

Kollmorgen

Part three of three: Example of a rotary axis needing a regenerative resistor

By Hurley Gill • Senior applications and systems engineer | Kollmorgen Please refer to part one and part two of this three-part series for background information on the functions and types of regenerative resistors for servo applications. Let’s now consider the worst-case deceleration of an axis needing to reach a zero velocity for a p-stop […]

Part two of three: Servo-system regenerative resistor types and accessories

In the first installment of this series, we explained the regenerative-power requirements for the controlled motion of servomotor systems. Here we detail common electrical protection circuitry. By Hurley Gill • Senior applications and systems engineer | Kollmorgen Designing a machine with servomotors, drives, and regenerative resistors requires consideration of numerous design factors. These components affect […]

Part one of three: Selecting regenerative resistors to harvest servomotor energy

Here we explain the data required for determining regenerative-power requirements and regen-resistor selection for the controlled motion of servomotor systems. By Hurley Gill • Senior applications and systems engineer | Kollmorgen Electric AC servomotors are either synchronous or asynchronous motors used in a closed-loop (servo) configurations for precise output control. Control over motion outputs — […]

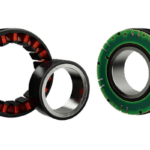

Kollmorgen debuts new generation of robot-ready frameless servo motors

Kollmorgen has introduced the new TBM2G series of frameless servo motors, introducing features that simplify the design of collaborative, surgical, aerospace and defense and other robots while delivering optimal performance in a lighter, more compact package. These new motors will complement Kollmorgen’s existing TBM and KBM series of frameless motors. Resulting from several years of […]

Kollmorgen adds new controller to QMP-SynqNet controller series

Kollmorgen’s QMP-SynqNet Series is an ultra-high-performance multi-axis controller for precision applications. It incorporates a 64-bit 1.2-GHz processor for maximum axis count, with servo update rates up to 48 kHz supporting up to 64 axes and 64 SynqNet nodes. Kollmorgen recently introduced the QMP-LT (Lite), an economical version that offers the same features and functionality as […]

Breaking the old rules of inertia matching for servo applications

Modern servo drives with advanced tuning capabilities — when paired with performance servo motors having high-resolution feedback — can eliminate load-to-motor inertia-mismatch concerns. By the Kollmorgen engineering staff The accepted principle of matching motor to load inertia is no longer pertinent with today’s faster motion-control processors and advanced control algorithms. This outdated inertia-matching method of […]

Improving performance without machine redesign

Improving machine performance to meet market demands doesn’t have to mean starting over from scratch. By partnering with a motion-centric supplier that offers new-generation motion systems plus co-engineering expertise to provide perfect-fit customizations, aging machines can be brought back to life with minimal design impact. As new technologies enter the industrial market, engineers must find […]

New matched motor-drive motion system from Kollmorgen

Kollmorgen’s new 2G Motion System is a servo solution based on the latest thinking about single-source, systems-based design. The 2G Motion System was designed specifically to harness the performance capabilities of Kollmorgen’s AKD2G servo drive and AKM2G servo motor. Motor and drive are precisely matched in every element (e.g. drive switching frequency, commutation algorithms, motor […]

Environmental effects on motion components in robots

Here we outline leading factors affecting the longevity and performance of industrial robot joints. Links refer to supporting research listed at the feature conclusion. Recent years have seen continuous demand in numerous industries — automotive manufacturing to computer, communication, and consumer electronics (3C) product fabrication — for industrial robots. Compared to automated dedicated equipment in […]