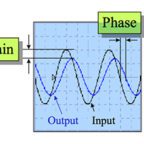

A servo drive can include any combination of three types of control loops—a position loop, a velocity loop, and a current loop. While each loop’s purpose is to control a different aspect of the motor’s performance, they are all characterized by a common parameter: bandwidth. The bandwidth, or response time, of the system is a measure of how fast it responds to the changing input command. In other words, the bandwidth of the control loop determines how quickly the servo system responds to changes in the parameter being controlled—position, velocity, or torque.

Image credit: nctu.edu

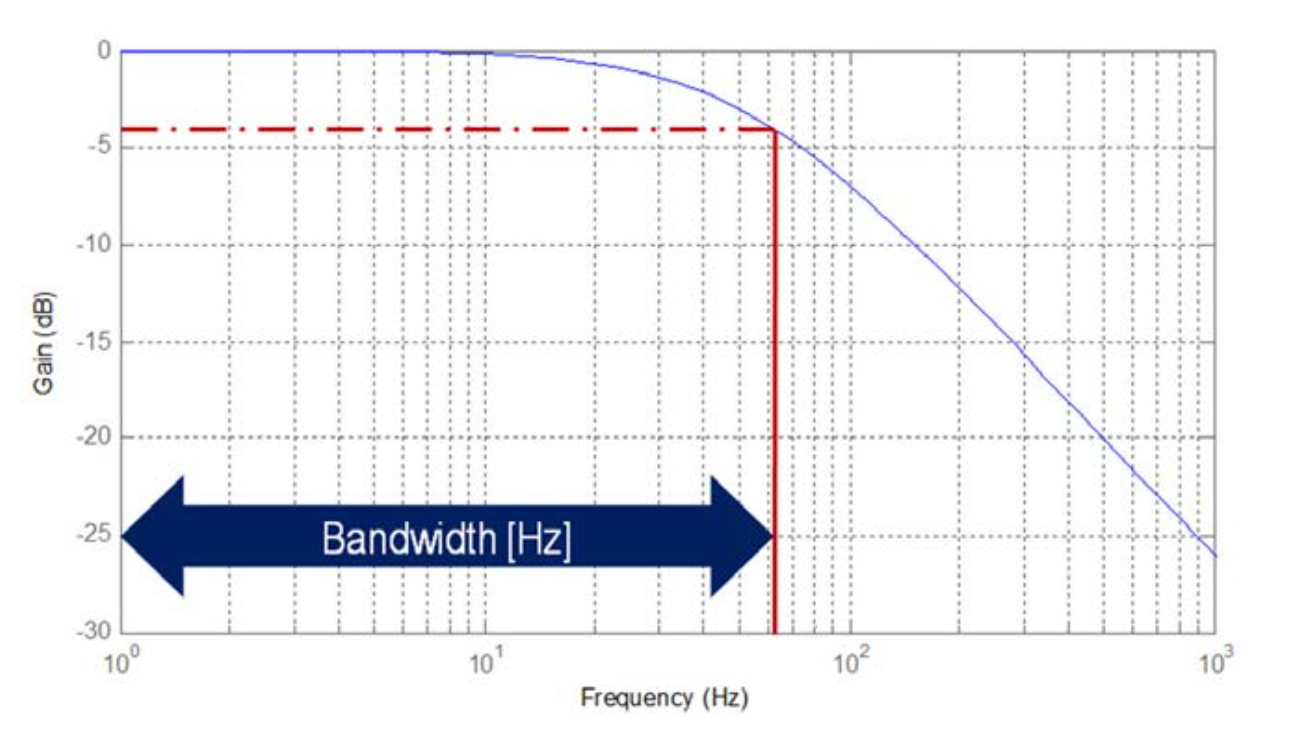

In servo drives, the bandwidth of a control loop is defined as the frequency at which the closed-loop amplitude response reaches -3 dB. At this point, the output gain (ratio of output to input) equals approximately 70.7% of its maximum, and the output power (power delivered to the load) equals 50% of the input power. (This article further explains the relationships between amplitude response, output gain value, and output versus input power.)

While higher bandwidth generally provides stiffer motor performance, decreases error, and improves transient response time, there are also drawbacks to high bandwidth in servo systems. Specifically, the higher the bandwidth, the higher the frequency at which the motor responds to disturbances, which typically requires higher accelerations and forces.

Power dissipation has a squared relationship to force, so any increase in bandwidth significantly increases power dissipation (i.e. heat), and therefore, the temperature rise of the motor. And because temperature is a limiting factor in motor operation, the motor characteristics may actually limit the allowable bandwidth of the servo drive.

Note: Other components in the system — including the resolution of the feedback device, the update rate of the drive, the motor-load inertia ratio, and the rigidity of the motor-load coupling — also affect the maximum achievable bandwidth of the drive.

Leave a Reply

You must be logged in to post a comment.