One way to improve servo system performance is to increase the gains in the control loop, allowing the system to respond faster to commands and to settle more quickly, with less oscillation. But increasing the servo gains means that any resonances in the system — typically due to mechanical compliance — are further amplified, which can […]

Servo Motors

What is external device monitoring and how does it relate to machine safety?

According to the Machinery Directive 2006/42/EC, technical protective measures should be used to reduce risks that cannot be avoided through safe design measures. These technical protective measures include safety devices such as door locks, covers, light curtains, and other equipment that monitors the machine movements. When the safety device controls and external device, such as […]

What machine safety functions address speed, and when are they used?

The Machinery Directive 2006/42/EC states that when a machine manufacturer is unable to eliminate the risks of potential hazardous situations (for example, mechanical hazards such as crushing or cutting) through safe design methods, the next step is to reduce the risks through technical protective measures. These technical measures include protective devices, such as door locks […]

STXI Motion expands integrated closed-loop servo-stepper motor line

The stepIM NEMA 17 EtherCAT model from STXI Motion is the newest addition to the company’s family of integrated closed-loop servo stepper motors. The IP65-rated stepIM NEMA 17 delivers an efficient and economical solution for applications requiring the performance of a servo at the price of a stepper. “The new stepIM NEMA 17 closed-loop stepper […]

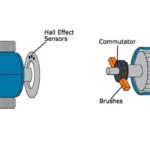

Which types of DC motors can be used as servo motors? (And a refresher on DC motor technologies)

Servo motors are used in applications where precise control of position, speed, or torque is required. But many different types of motors can be considered servo motors — the defining feature of a servo motor is that it incorporates or reads feedback in a closed-loop system. In fact, although many servo applications use synchronous AC motors, […]

AutomationDirect adds new servo systems for motion control applications

AutomationDirect has added LS Electric servo systems that provide extremely accurate motion control and include the most requested features — setup wizards, auto-tuning, built-in indexer, and more — in an extremely cost-effective package. The L7S family of brushless servo systems is fully digital and capable of covering a broad range of motion control applications. There […]

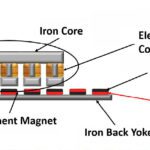

How do manufacturers address cogging in linear motors?

Iron core linear motors are known for their high continuous and peak force capabilities, good thermal management, and excellent force-to-size ratio. But they’re also known to produce cogging forces, which lead to force ripple, or variation in output force. But how much of a problem is cogging for iron core linear motors, and what are […]

When is dither helpful in motion control systems?

Dither is one of several terms used to describe small, rapid, back-and-forth movements of an object. Depending on the context, when the term “dither” is used in motion control systems, it can refer to purposeful, commanded movements or to unintended, unwanted motion. In some motion systems, dither is purposely induced to reduce the effects of […]

JVL expands line of integrated spindle drive motors with absolute multi-turn encoders

JVL A/S has introduced a new addition to its ServoStep line of motors, a directly mountable motor for driving spindles. It’s perfect for replacing hand wheels in format change applications. ServoStep has everything built-in including motor, encoder, drive electronics, control electronics with ePLC and optional Ethernet or CAN bus integrated into one compact unit. All […]

New compact servo motor features integrated positioning controller

maxon’s new IDX compact integrated servo gearmotor + drive combines a powerful, brushless EC-i motor and an EPOS4 positioning controller with field-oriented control (FOC), which can be complemented with a maxon planetary gearhead when required. This integrated motor stands out for its high torque density, high efficiency, maintenance-free components, and a high-quality industrial housing providing […]