Image credit: Celera Motion

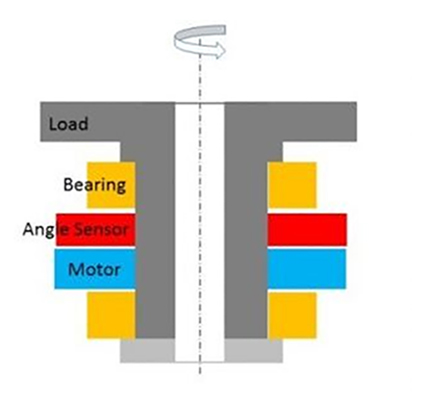

In the most common motor-driven systems, the motor is coupled to the load being moved by a mechanical transmission element — a belt, chain, rack and pinion, ball or lead screw, or even simply a gearbox. But some linear and rotary motion systems do away with mechanical transmission elements and couple the load directly to the motor. These are referred to as direct drive systems.

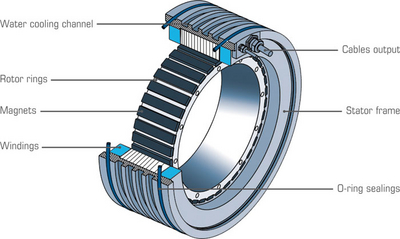

There are several types of linear and rotary direct drive systems, ranging from linear motors and torque motors to voice coils and some piezo motor designs. Linear motors and torque motors are arguably the most common types, used in everything from packaging and assembly equipment to machine tools and six-axis robots, where high acceleration and compact form factor are key benefits. For nanopositioning or small-stroke, oscillating applications, the direct drive principle of voice coil motors and some piezo motor designs, such as the bending and ultrasonic versions, means extremely high rigidity and excellent positioning accuracy.

In addition to the benefits inherent to each specific technology, direct drive systems all have several characteristics in common. First, the elimination of mechanical transmission components means no backlash, windup, or compliance in the system, so stiffness is significantly improved. And better stiffness means increased positioning accuracy and repeatability, as well as reduced resonance — so servo controls can be tuned with higher gains. Direct drive systems can also tolerate higher load-motor inertia ratios, without compromising the motor’s ability to control the load.

Image credit: ETEL S.A.

Direct drive systems also benefit from lower friction than systems that use mechanical transmission components, so torque or force requirements are lower. Heat generation is also reduced, which means less power is lost between the motor and the load — which improves system efficiency.

Although friction is generally seen as an undesirable effect of relative motion between two components, the reduced friction inherent in direct drives can be a downside in some applications. For example, with direct drives, there is very little resistance to back driving, so a linear direct drive system used in a vertical application will require an external brake or other measure, such as a counterweight, to prevent the load from falling if power is lost.

The friction and compliance inherent in mechanical transmission components can also provide damping for vibrations and oscillations, whereas direct drive systems typically provide less damping for these effects, which can mean an increase in settling time.

Image credit: TorqueTec GmbH

Eliminating mechanical transmission components also has the benefit of reducing the inertia of the system. In some applications — for example, where high thrust forces would dictate a large diameter ball screw drive — less inertia makes it possible to use a smaller motor. And a system with lower inertia can be accelerated and decelerated more quickly, making it easier to achieve highly dynamic moves and faster stops, which can be especially beneficial where the load could present a danger to other equipment or personnel.

Direct drive systems also offer benefits over traditional systems in terms of maintenance and lifetime. First, with fewer wear components, lubrication needs are minimized and spare parts inventory is streamlined. And the elimination of mechanical components that can experience premature wear or failure means that direct drive systems can often achieve longer service life than systems using belts, ball screws, or other mechanical transmission components.

Leave a Reply

You must be logged in to post a comment.