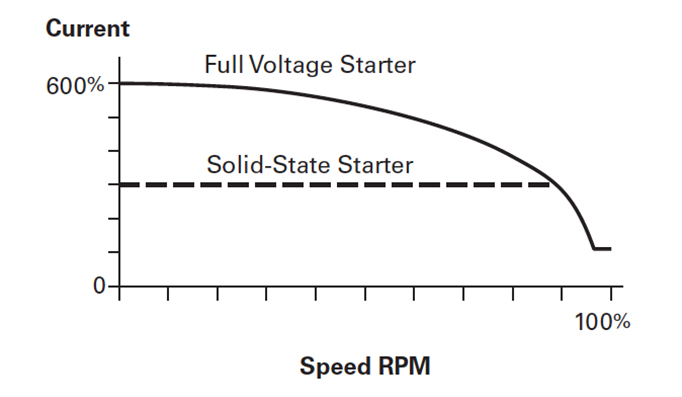

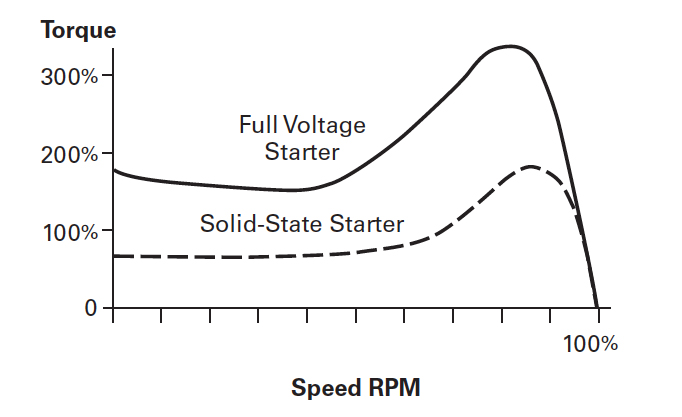

The traditional method of starting an AC induction motor “across the line” results in full voltage, current, and torque being applied immediately when the motor is started, and likewise, being removed immediately when the motor is stopped. While this is the most simple starting method, the high inrush current (often 6 to 7 times the motor’s rated current) and peak starting torque can damage the motor, driven equipment, and product. Across the line starting also causes high peak power demand, which can trigger peak demand fees from the utility company.

A soft starter can eliminate these problems by gradually increasing voltage to the motor terminals during startup, providing a controlled ramp-up to full speed. This lowers inrush current and controls starting torque, reducing mechanical shocks to the system and to the product.

Image credit: WEG Electric

Soft starters are also known as reduced voltage soft starters (RVSS).

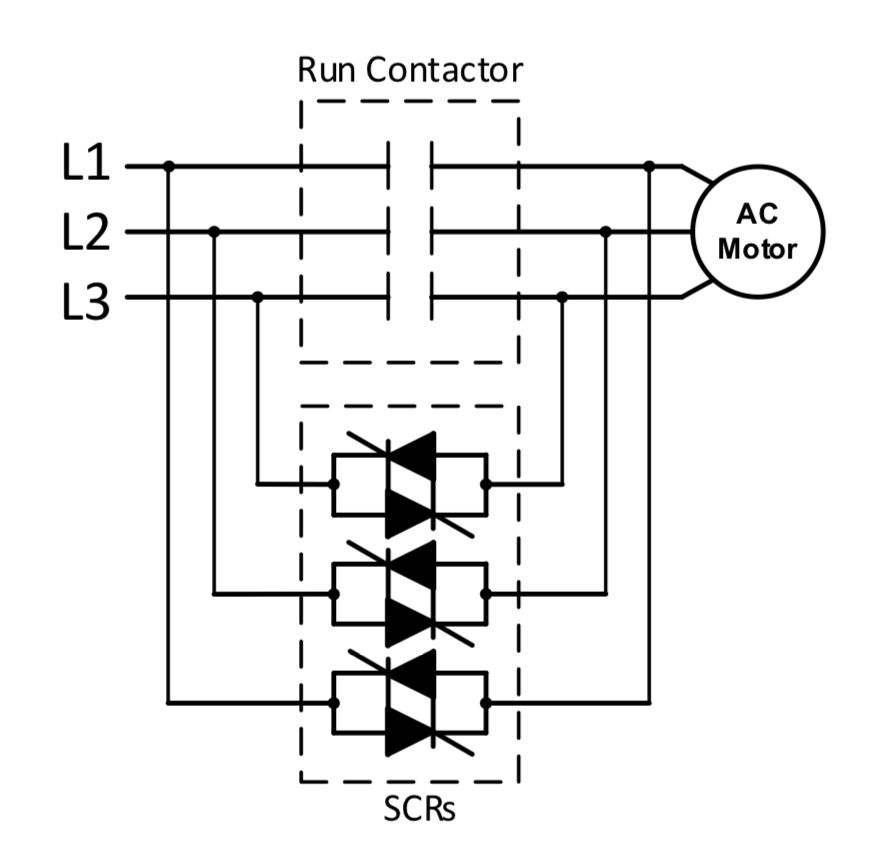

A soft starter relies on three pairs of SCRs (silicon controlled rectifiers) — one pair for each phase of power — that are applied gradually for portion of each voltage phase, limiting the voltage provided to the motor. In turn, current is reduced proportionally to the reduction in voltage. Torque, however, is proportional to the square of the voltage, so even a small reduction in voltage results in a large reduction in torque. For example: a 50 percent reduction in voltage yields a 50 precent reduction in current and a 75 percent reduction in torque.

![]()

Where:

T2 = Torque at reduced current/voltage

T1 = Torque at locked rotor current

I2 = Reduced current

I1 = Locked rotor current

V2 = Reduced voltage

V1 = Full voltage

Once the motor is up to speed, the soft starter is bypassed and the motor is connected across the line, allowing full power to the motor terminals. Soft starters introduce almost no harmonics into the system and typically have efficiencies of 99 percent or better.

Image credit: Eaton Corporation

It’s important to note that a VFD (variable frequency drive) can provide the same controlled starting and stopping functions that a soft starter provides, albeit in a different way — by varying the frequency of the voltage, rather than by controlling the amount of voltage, supplied to the motor. VFDs offer other benefits over soft starters, the most significant being the ability to control motor speed throughout the operating range. VFDs can also provide holding torque (full torque at zero speed), which is critical in applications such as elevators and cranes.

For applications such as conveyors and fans that require speed and torque control or current limiting during starting and stopping — but run at constant speed otherwise — soft starters provide a simple, economic solution in a small footprint.

Leave a Reply

You must be logged in to post a comment.