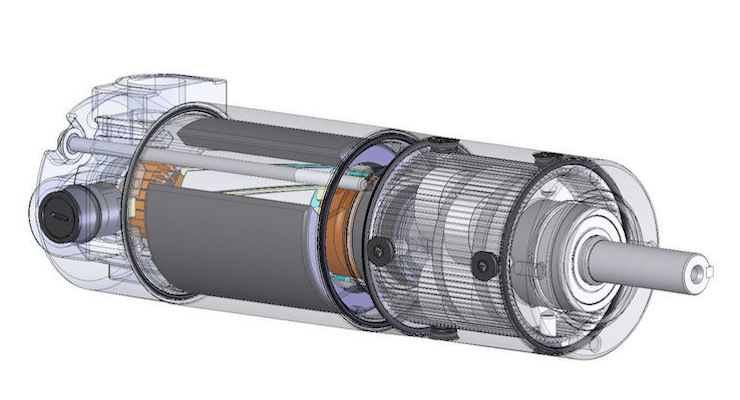

Updated 2020 ⚙️ Gearboxes provide torque multiplication, speed reduction, and inertia matching for motor-driven systems. Servo systems, specifically, require gearboxes that can supply not only high torque with low added inertia, but also high precision and stiffness. One type of gearbox meets all these criteria while providing relatively long operating life with low maintenance requirements — the planetary gearbox.

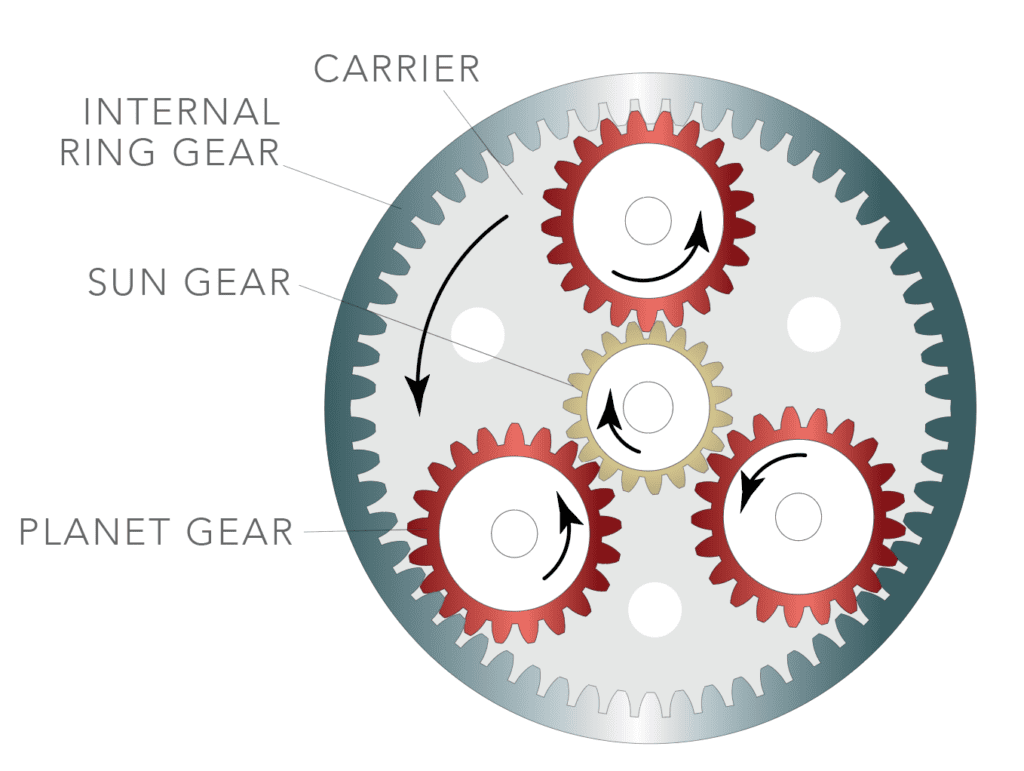

A planetary gearbox consists of multiple planetary gears that revolve around a central sun gear while engaging with an internal gear and rotating on their own axes. The continuous engagement of the planetary gears means the load is shared by multiple teeth, allowing planetary designs to transmit high torque loads.

This load sharing among teeth also gives planetary gearboxes high torsional stiffness, making them ideal for processes that involve frequent start-stop motions or changes in rotational direction, which are common characteristics of servo applications. Most servo applications also require very precise positioning, and planetary gearboxes are designed and manufactured to have low backlash, with as little as 1-2 arcmin in some cases.

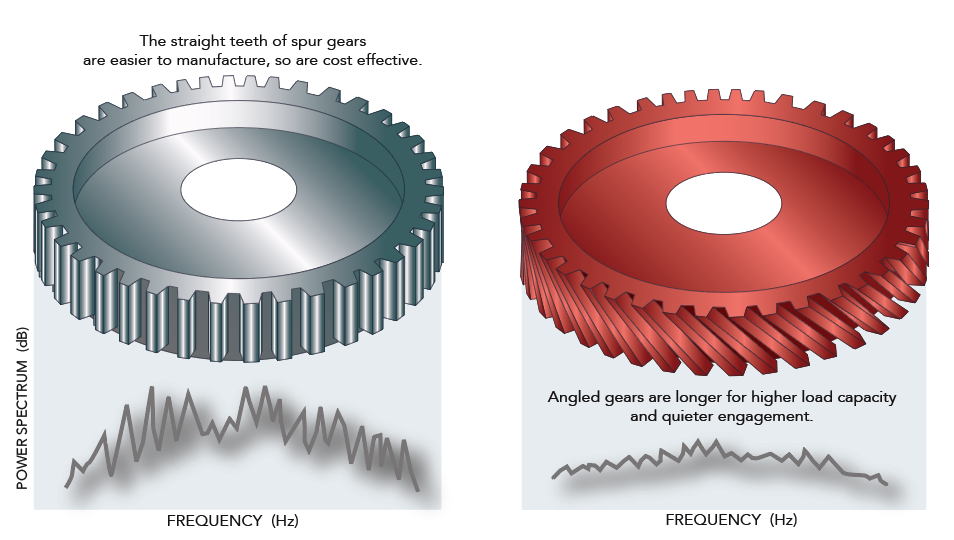

Note: Planetary gearboxes can use spur or helical gears. While spur gears can have higher torque ratings than helical gears, helical designs have smoother operation, less noise, and higher stiffness, making helical planetary gearboxes the preferred gearbox for servo applications.

When a gearbox is added to the drivetrain, the rotational speed delivered from the motor to the driven component is reduced by the amount of the gear ratio, which can allow the system to make better use of the servo motor’s speed-torque characteristics. Planetary gearboxes are able to accept very high input speeds and provide speed reduction of up to 10:1 for standard designs, with high-speed designs providing gear ratios (and, therefore, speed reduction) of 100:1 or higher.

Planetary gearboxes can be lubricated with either grease or oil, although a planetary gearbox for servo use (sometimes referred to as a “servo rated” or “servo” gearbox) is often lubricated with grease. In either case – grease or oil lubrication – planetary gearboxes are often lubricated for the life of the gearbox by the manufacturer, which eliminates maintenance for the end user.

The most important benefit of using a gearbox in a servo system is arguably its effect on the inertia of the load. The load inertia, which is reflected to the motor, is reduced by the square of the gear ratio. So even a relatively small gear reduction can have a significant effect on the inertia ratio.

![]()

Where:

JL = inertia of load reflected to motor

JM = inertia of motor

![]()

Where:

JD = inertia of drive (screw, belt & pulley, or actuator)

JE = inertia of external (moved) mass

JC = inertia of coupling

JG = inertia of gearbox

i = gear ratio

While a “perfect” inertia ratio of 1:1 is impractical in many cases, the goal of most servo system designs is to keep the inertia ratio as low as possible in order to achieve high system responsiveness. Reducing the load inertia by adding a gearbox to the system means that a smaller motor (with lower inertia) can be used, while still maintaining a desirable ratio between the motor and the load. Plus a planetary gearbox, by virtue of its compact design, has a low inertia itself, adding only a small amount to the load inertia that the motor must balance.

Leave a Reply

You must be logged in to post a comment.