AC drives capable of operating at frequencies of 600 Hz or greater are generally referred to as “high-frequency” drives. These drives are considered by the U.S. and the EU to be dual-use devices, meaning that although they are commonly used in civilian applications, such as industrial equipment, they can also be used in military applications or […]

Servo Drives

Motion controllers help planes take precision aerial photos of disasters

Quick response to catastrophes such as floods and fires is critical, but disaster sites are often inaccessible and unsafe for inspectors and adjusters who come after first responders. Now Pictometry, an EagleView company, collects and supplies ultra-clear aerial photography to let insurance carriers, restoration companies, utilities, and contractors identify safe-access points, areas of total loss, […]

FAQ: How to tune servo systems for high dynamic response?

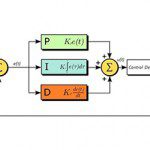

The purpose of a servo control loop is to minimize error, and this is often done through the use of PID (proportional-integral-derivative) gains, which correct errors between the target value and the actual value. But the PID algorithm is reactive, and takes time to respond. Case in point: the proportional term requires an error in order […]

Crossover frequency: How is it used in servo motor tuning?

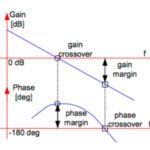

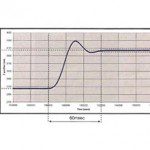

A common method for evaluating a servo system’s stability is to determine the system’s frequency response, which involves measuring the gain margin and phase margin at the crossover frequencies. To understand how gain and phase crossover frequency is used to determine stability, let’s look at exactly what it represents, using a Bode plot. Closed loop systems are difficult […]

FAQ: What are servo motor current, velocity and position loops and bandwidths?

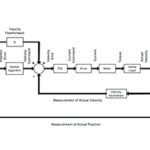

Servo motors operate in a closed-loop system, which includes a feedback device, a drive (amplifier), and a controller. The controller uses output from the feedback device to compare the commanded value (position, velocity, or torque) to the achieved value and issues commands to the drive to correct any errors. This process of monitoring feedback and […]

FAQ: What is the closed-loop frequency response of a servo motor?

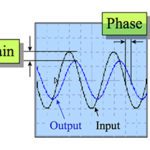

For a system driven by sinusoidal inputs, such as a servo motor, frequency response is a measure of the amplitude and phase of the output signal relative to the input signal. It is a useful estimate of the limits of servo tuning that will produce a stable system without oscillation. To determine frequency response, a sinusoidal input […]

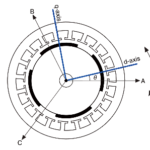

Field oriented control vs. sinusoidal commutation

Brushless AC (BLAC) motors are driven with sinusoidal AC currents, and due to skewed magnets and sinusoidally distributed windings in their stators, they also produce sinusoidal back EMF. Sinusoidal commutation is a common way to control BLAC motors, as it provides a very consistent torque output with little torque ripple. But at high speeds, sinusoidal […]

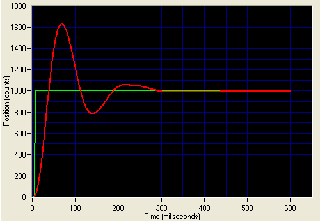

FAQ: What are servo feedback gains, overshoot limits, and position error limits?

Servo tuning can be accomplished by several methods, but the most common way is to use a PID algorithm. The PID algorithm uses three feedback gains—proportional gain, integral gain, and derivative gain—to compare the commanded position (or velocity) with the actual value and issue commands to correct errors between the two. Feedback gains determine how […]

FAQ: How are the controls for servo motors tuned?

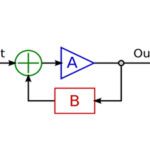

Servo motors are used in closed loop systems and operate based on error feedback—the comparison of a target value to the value actually reached by the motor/load. Because mechanical systems have inertia and compliance, the target value is rarely achieved on the first position command—hence, the need for feedback and correction commands. Servo tuning is […]

FAQ: What is settling time in a motor-driven servo system?

One of the unique characteristics of servo systems is that they operate in closed-loop mode. This means they use feedback—from a resolver or encoder on the motor, and sometimes from an encoder on the load—to compare the commanded value (typically position, speed, or torque) with the value that was actually reached. Based on this feedback, […]